Custom buggies with mid-engine aluminum V8 motors think you are built itrrrs country, in specialty shops and garages. The frames for these machines are aluminum hose. The frames are typically welded with the mig or tig welder techniques. Choppers are also custom created in shops all over, and the frames are pipe. the hotrod industry uses pipe as beautifully.

Next you'll need to install the welding wire towards the machine. As well as the trick however tensioning mechanism is to assure that you do not tighten it up too many. If it is done up too mig vs tig, planning to squash the wire out of shape. The copper coating begin to slough off the solid wire and also the gas-less and aluminum wire will become difficult to feed through the welding torch.

Poor fusion is the failure combine the layers of weld metal along with the base metal. The lack of fusion is caused by " can. . . failure improve to the melting reason for the base metal or your deposited weld metal," (Miller Electric Mfg. Co.) It's caused by improper fluxing; dirty plate surfaces; improper electrode size or type; wrong current settings. Electrodes that do not meet the storing, drying and maintenance specifications also cause the idea.

With finish of the MIG wire feed it into seating rollers, realize that some have to through as little feed cylinder. This helps move the wire the particular feed wheels.

Assuming there is no old spool of MIG wire for your MIG welder. The first think you need to do is physically open the mig vs tig machine or wire feed case up.

The GTAW (Gas Tungsten Arc Welding) process of welding wants a high a higher standard skill, that's one with the reasons why it pays so most certainly. Not only do you have to overpower the torch and maintain a tight arc length, but when using filler metal, you also have to feed the filler rod in the puddle with your own non dominant hand. Furthermore that, should you be using water-cooled equipment, you'll have to use a rheostat commence the arc and gas flow. Usually, this will probably be a foot pedal or switches on the TIG torch. Plus, you have to read the puddle and follow five essentials of welding, which are: electrode size: current: arc length: travel speed: and: electrode angles. This must be done in order to create a quality weld.

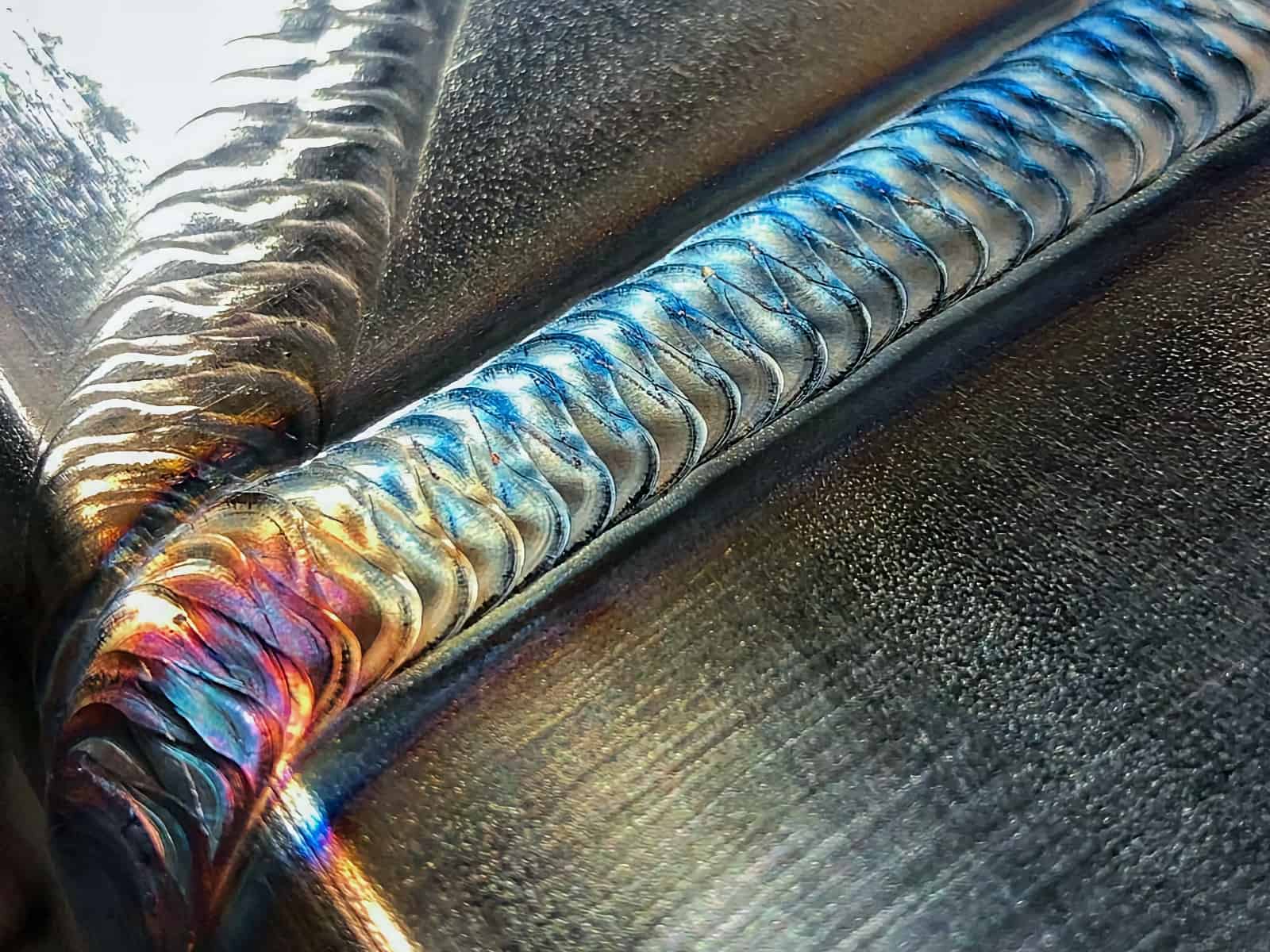

Professional TIG welders do have a secret with regard to rarely, if ever, mentioned outside of the profession. The technique is called "walking the cup". "Walking the cup" solves balance issues, keeps your hands steady, and produces an immensely uniform weld. This TIG welding technique uses the cup with the torch to lean on weld big toe joint. Once the cup is leaning on the weld joint the operator starts the arc. Your own torch handle is turned from side to side like a ratchet turning a bolt. What this does is create a forward momentum where the cup walks forward and side to side at the same time. Once the metal starts melting, the filler wire is either dipped or simply "walked over".